Selecting the appropriate seafood processing equipment plays a central role in achieving efficiency and product consistency, regardless of whether operations are onboard vessels or within land-based facilities. The equipment in use must support various types of seafood and withstand fluctuating workloads and demanding environments. With a broad array of options available, finding the ideal solutions for each operation can significantly influence productivity and product quality.

Accessible resources that enable users to browse and filter by function or type make evaluation and selection manageable, even for facilities with unique or shifting needs. One practical way to discover suitable equipment options is to consult a collection of seafood processing equipment designed specifically for the sector. With solutions tailored for numerous applications, it becomes easier to adapt to changes in processing volume, species, and regulatory requirements.

Overview of seafood processing equipment

Seafood processing equipment handles essential steps throughout the value chain, such as sorting, cleaning, filleting, weighing, and packaging. Each machine serves a targeted role—grading machines assess size and quality, filleting systems ensure precision, freezing units extend product shelf life, and automated packaging lines prepare processed seafood for market distribution.

Materials and design are selected to address hygiene and durability. For example, stainless steel constructions and layouts with accessible surfaces allow for easy cleaning and maintenance, supporting compliance with food safety standards.

Compatibility with variable operating environments is also fundamental. Machinery used at sea must cope with limited space and constant motion, while structures in shore-based plants are often larger and integrated into broader facility networks. Adaptable solutions can withstand seasonal changes, diverse species, and stringent industry regulations, ensuring that every step from catch to shipment meets expectations.

Onboard and land based solutions

Modern seafood facilities span from compact vessels to large shore-based factories, each requiring specialized equipment to maintain efficiency and quality. Ensuring seafood remains in optimal condition demands a customized approach to both space and process design.

Meeting diverse processing needs

Facilities working at sea contends with constraints like limited floor space and constant movement, necessitating compact and robust systems. Features like space-saving layouts and reinforced construction are critical in these contexts, where reliability and ease of use are essential due to the challenging operating environment.

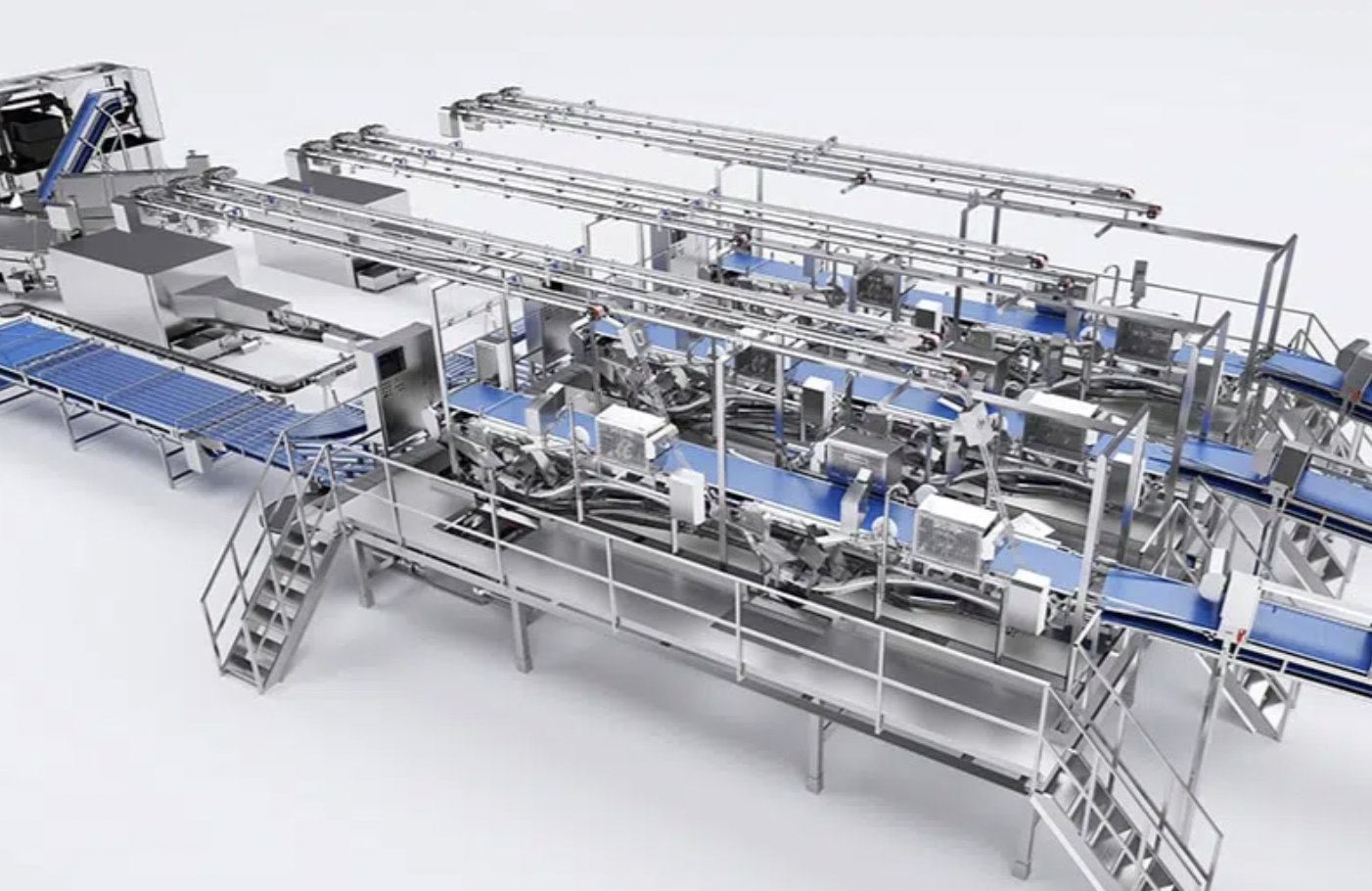

In contrast, land-based plants often prioritize high-volume throughput, integrating automation and larger scale machinery. Scalability and system integration are vital, with conveyors, graders, and portioners forming continuous production lines that meet facility goals. Matching the equipment to the processing scale, installation environment, and material flow ensures seamless transitions between different tasks and stages.

Adaptability for various species

Processing seafood involves a variety of raw materials, ranging from shellfish and crustaceans to pelagic and whitefish species. To accommodate these, processing lines must switch settings and components effectively, handling different catch types with minimal interruption.

Equipment featuring interchangeable components, variable-speed conveyors, and intuitive control panels allows for simple adjustments between processing tasks. Such adaptability supports operations as market demand, available species, and regulatory expectations shift over time. It is also beneficial for maintaining consistent output and minimizing downtime across diverse production cycles.

Design and manufacturing approach

Properly designed equipment can have long-term benefits for product yield, process reliability, and operational safety. Manufacturers who focus on these aspects supply machinery suitable for a wide array of seafood species and workflow requirements.

Product engineering and workflow optimization

Each processing unit is constructed with attention to engineering precision and long-term resilience, often utilizing corrosion-resistant materials for extended service life. Advanced design tools, such as 3D modeling, facilitate the creation of configurations custom-fitted to particular facility layouts and processing steps.

Adopting modular concepts makes it possible to expand or modify systems easily, adapting to changes in production demands. Simplified maintenance and enhanced cleanability contribute to steady operation, minimizing expensive downtimes and supporting strict food quality standards.

Range of offerings

Suppliers provide solutions that address every point of the processing chain: from initial sorting and grading to cooking, chilling, freezing, and automated packaging. These machines accommodate both shipboard and shore-based scenarios, with construction designed for consistent use in busy environments.

Automated control systems, sturdy assembly, and efficient energy usage feature prominently in these offerings. Equipment can be supplied either as stand-alone units or as elements within larger integrated production lines. Throughout, usability, cleanliness, and reliable operation remain constant priorities to satisfy industry protocols.

Product selection and functionality

Matching the right seafood processing equipment to an operation’s needs is a detailed process involving assessment of species handled, output volume, and process flow.

Filtering equipment by type

Sorting equipment by its suitability for onboard or onshore placement simplifies decision-making. Many providers categorize offerings by function—such as filleting, grading, washing, or conveying—making it possible to target solutions that align with specific stages of production.

Easy filtering helps narrow down choices, accommodating any combination of seafood, space limitation, or throughput requirement. Attention to these filters enables processors to maintain both flexibility and organizational efficiency.

Choosing products by function

Processing facilities often specialize in certain tasks, like portioning, sorting, or thawing. Opting for machinery equipped with modular features, stainless steel elements, and accessible cleaning points greatly enhances long-term productivity.

Reviewing equipment according to main production activities ensures investment in technology that supports seamless operations, adaptation to regulatory changes, and readiness for future growth. With this approach, facilities can achieve their goals while keeping pace with industry trends and maintaining seafood quality.